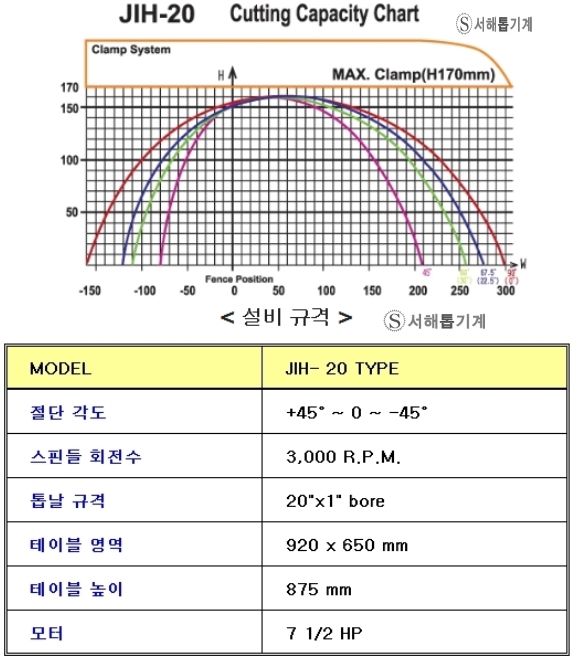

JIH-20 회전각절단기

덧글 0

|

2017-01-07 00:00:00

- Clamping system mover on linear quide way, that stable clamping

- Clamping system is controlled by an independent air cylinder

( 1+2 feature : Clamping pressure can be adjusted as desired to suit work piece type, that avoids damage on the work piece due to over-pressure ) - Adjustable clamping height

- Adjustable clamping speed

- Adjustable cutting speed

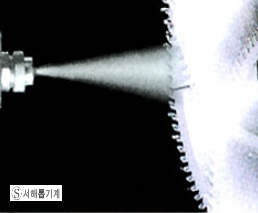

( 3+4+5 feature : According to work piece type to adjust the clamping height and speed and cutting height and speed ) - Accurately controlled oil mist system greatly improves lubrication and cooling effect, while reducing trouble to a minimum.

- The handle for convenient and easy fix worktable.

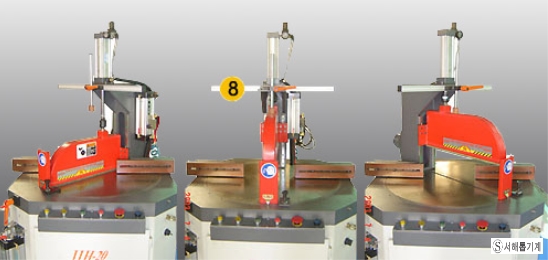

8.Hold handle for rotary worktable angular ( ± 0 ~ 45 degrees )

- Quick positioning button

- Quick positioning hole When equipped with the quick positioning button and the guick positioning hole, the freqently applied angles such as 22.5°, 30° and 45° can be fast positioned for increasing efficiency.

- The convenient door for saw blade replacing. Open the side door to replace the blade. The door can load the whole blade and there won't be any inconvenience for the blade installation as those Atyped machine

- CHIP OUTLET PORT The chips are exhausted through this outlet port. It eliminates inconvenient cleaning for those chip deposited in the machine.

VACUUM OIL MIST UNIT

The vacuum oil mist unit employs vacuum generation principle to transform cutting fluid into oil mist for splashing. It provides lubrication and cooling functions, ensuring no dust deposit and sawblade, high cutting accuracy and long service life of sawblad.

The vacuum oil mist unit employs vacuum generation principle to transform cutting fluid into oil mist for splashing. It provides lubrication and cooling functions, ensuring no dust deposit and sawblade, high cutting accuracy and long service life of sawblad.

- 경기도 시흥시 정왕동 군자천로 131번길 47 (시화공단 2라 501호)ㅣTEL : 031-431-5953, FAX : 031-431-5954 H.P : 010-8889-0545 l 사업자등록번호 : 134-05-46416ㅣ대표자 : 양금용

- Copyright © 2017 서해톱기계 All rights reserved.